-

Chapter 11: INDIAN MINES AND MINERAL WEALTH

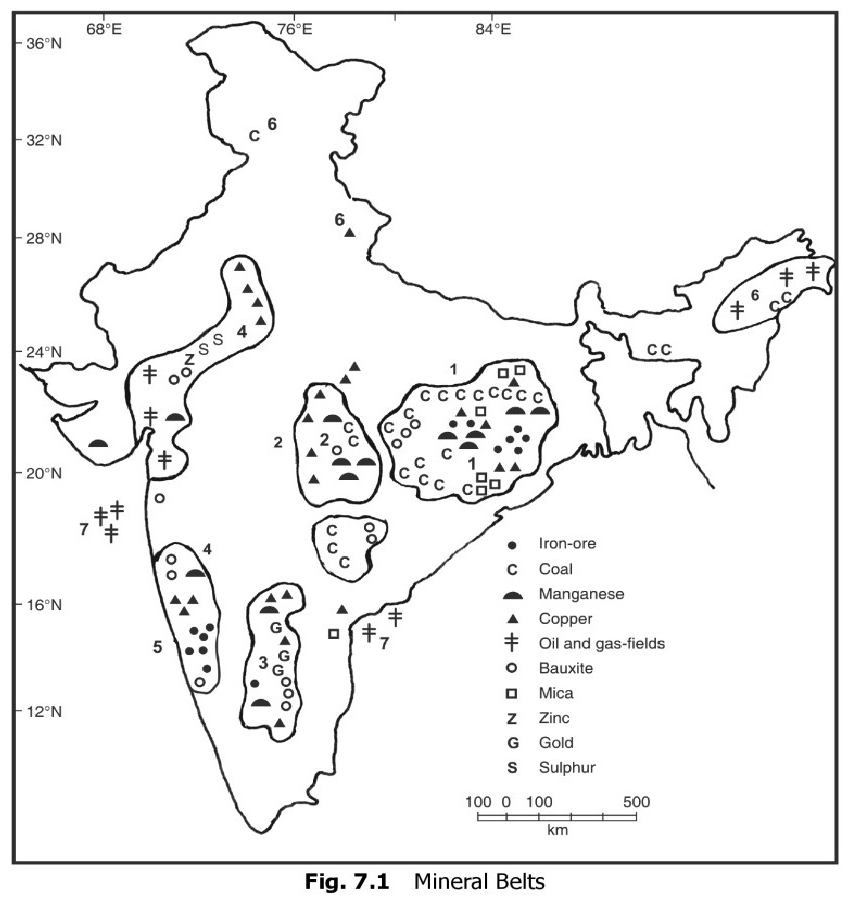

Mineral Belts of India

The Chotanagpur Belt:

This region contains almost 100% of kyanite reserves, 93% of iron ore, 84% coal, and 70% of chromite of the country.

The Midland Belt:

This belt sprawls over the states of Chhattisgarh, Madhya Pradesh, Andhra Pradesh, and Maharashtra. This belt is rich in manganese are, bauxite, mica, copper, graphite, limestone, lignite, marble, and limestone.

The Southern Belt:

It stretches over the states of Andhra Pradesh, Karnataka and Tamil Nadu. This belt is rich in gold, iron ore, chromite, manganese, lignite, mica, bauxite" gypsum, asbestos, dolomite, china-clay, and limestone.

The Western Belt:

This belt stretches over the states of Rajasthan, Gujarat,and Maharashtra. The belt is rich in non-ferrous metals.

The South - Western Belt:

This belt sprawls over Goa, Karnataka, and Kerala. It contains the deposits of iron ore.

The Himalayan Belt:

In general, the Himalayan belt is poor in metallic minerals.

The Indian Ocean:

The continental shelf of the Arabian Sea and the Bay of Bengal are rich in mineral oil and natural gas.

The seabed also contains high grade nodules (poly-metallic nodules) of manganese, phosphate, barium, aluminium, silicon and iron. The best quality of nodlules are found at a depth of about 4000 metres.

Introduction

Indian metallic and non-metallic mineral wealth:

1. Iron

2. Manganese

3. Copper

4. Mica

5. Chromite

Energy reserves:

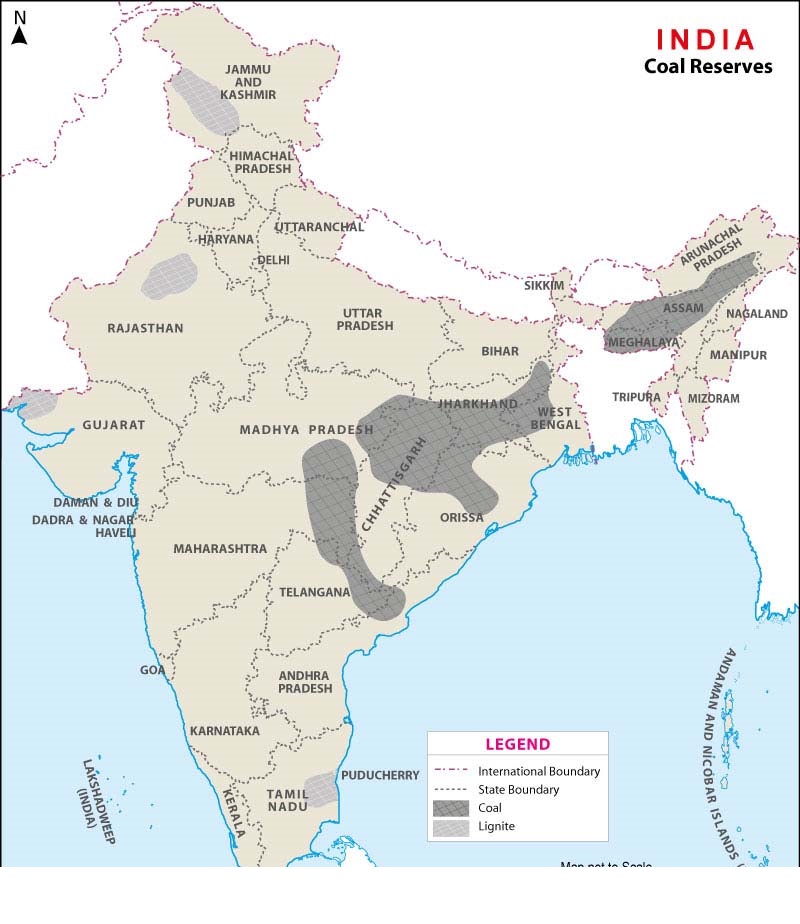

1. Coal

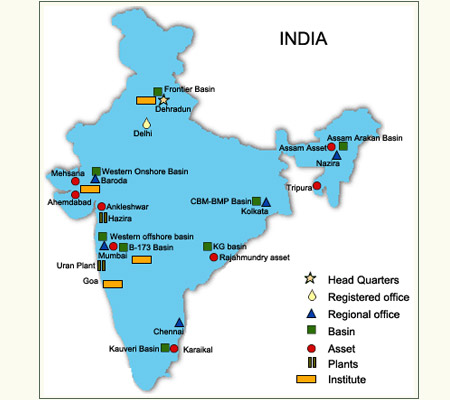

2. Petroleum

3. Uranium

4. Thorium

Correlation

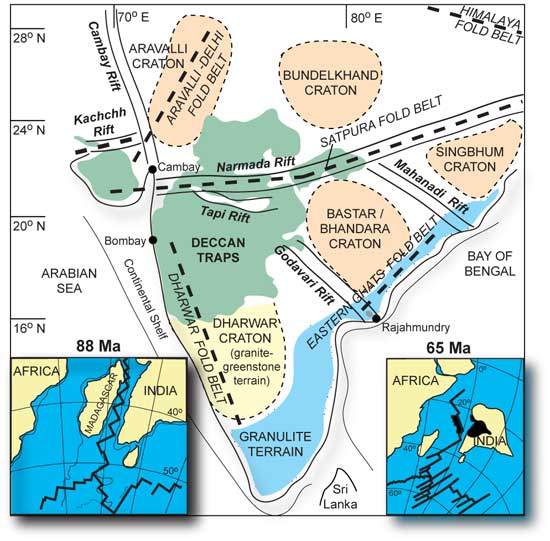

between shield regions and metallic mineral regions:

1. Shield region: Aravalli, Singhbhum, Dharwad

Fig 1: Shield regions and Rift valleys of India

2.

Metal

mines:

Chotanagpur and Dharwad plateau

Coal reserves

are located around the rift valleys like Damodar, Mahanadi,

and Godavari.

Fig 3: Coal reserves of India

Petroleum reserves are located along the Saurashtra shelf, KG basin, Bengal Bangladesh shelf, Brahmaputra shelf.

India has 22 refineries 17 are public sector, 3 are private and 2 are joint venture. India imports crude oil and exports petroleum products. India’s refining capacity is more than the demand.

Fig 4: Petroleum

reserves of India

Mineral regions:

1. Peninsula – bauxite

2. Himalayas – anthracite coals, limestone

3. Coastal areas – salt, thorium

The mineral rich

belt in India has five locations:

1. Chotanagpur plateau

· Kynite, iron, chromium, mica and coal.

·

Assam

petroleum reserve.

2. Chattisgarh region

· Iron, limestone and coal field in Godavari - Wardha belt

3. Southern belt – East Karnatak + AP

· Iron – Bellary

· Lignite – Neyveli

·

Mica,

lignite, coal – Nellore

4. South west belt

· Iron – Ratnagiri, Goa, Dharwad

5. North west belt

· Petroleum – Rajasthan and Gujarat

· Pyala lake – depression in desert filled with water. When water dries salt and minerals are left.

Types of Iron ore:

1.

Magnetite

:

electronic industries [70% - iron]

2.

Hematite

:

iron and steel industries [2nd largest producer after

Russia] [ 65% - iron]

3.

Limonite

:

pigment for manufacture of paints [50% - iron]

4.

Siderite

:

source of manganese and magnesium

Iron

reserves located in:

1. Jharkhand – Hazaribag, Singhbhum

2. Odissa

3. Maharashtra – Ratnagiri

4. Goa

5. Karnatak- Bellary, Chitradurga

6.

Chattisgarh

–

Bailadila

Manganese:

1. Jharkhand – all iron producing regions, Chaibasa – biggest

2. MP – Balaghat

Mica:

Odissa – Kodarma [largest in the world]

Uranium:

NPCIL extracts uranium and processes it to get yellow cake which is magnesium diurnate. Yellow cake then processed to uranium dioxide in hyderabad [nuclear fuel complex]. NFC sends it to all reactors.

India's three step nuclear program:

Nuclear

reactions:

1.

Fission:

U-235 is hit by neutron and it breaks into barium, krypton and

energy also neutrons are released. This is the reaction for

nuclear reactors, atom bombs.

Natural

uranium is 99.3% fertile i.e. U-238 and 0.7% fissile i.e.

U-235. The fissile element has the ability to fission in

excited state. The fertile has to be converted to fissile by

adding neutron i.e. Pl-239.

TABLE 1: INDIAN REACTORS

|

Heavy water reactor |

Light water reactors

|

|

Natural uranium as fuel |

Fissile uranium as a fuel |

|

Coolant is deuterium oxide [collides neutrons and hydrogen and slow them down, this induces future fission's] |

Coolant is distilled water [absorbs more neutrons than needed and so enrichment of uranium necessary frequently] |

|

By product is plutonium, tritium |

|

|

Frequent refueling, less heat generated |

More energy/unit ; expensive enrichment |

Criticality

of Reactions:

If more than one

neutron available for collision then reactor is super-critical;

if only one is available then critical and less than one means

sub critical. To reduce the rate of reaction a neutron absorbent

like boron or cadmium is inserted.

Thorium is

present in largest quantities in India. It is used in thorium

based reactors to get energy.

India's

three step nuclear program:

Step 1: P.H.W.R use uranium + D2O to get plutonium + energy

Step 2: Fast Breedor Reactors use plutonium + uranium oxide to get U-233 + energy

Step 3: Thorium based

reactors use Thorium+U-233 to get energy

BARC processes

used fuel in P.H.W.R to get reactor grade plutonium for fast

breedor reactors. FBR use liquid sodium as coolant and produce

more fuel than they consume. FBR to be at kalpakkam.

Thorium based reactors can be constructed only after successful operation of FBR for 30-40 years.

Nuclear liability law in India:

1. Required for US companies to get insurance in their countries.

2. Supplier of defective parts can be sued for damages by the operator [N.P.C.I.L]

3. The problem with the law is India is a signatory to international convention for supplementary compensation [I.C.S.C] that doesn’t allow this. Private parties may not have the capacity to bear such damages. But this shall save tax payers money in case of nuclear calamities.

4. To counter this deadlock the nuclear insurance pool was created with Rs.1500 crore by government and state owned insurance. Now suppliers need to pay the premium. The pool will cater to operators and suppliers.

5. In case of damage, pool will be used to cater to victims, the government will bear additional liability of Rs.1100 crore and additional liability shall be borne by I.C.S.C.

Fusion:

Hydrogen

atoms merge to form helium and enormous energy is released. This

is the prinicple for hydrogen bomb and energy from sun.

Indian coal:

a. It is Gondwana formation. Not coking coal or metallurgical coal

b. It has high ash fusion temperature

c. It has low sulphur content and high ash content.

d. It has low calorific value.

Problems:

a. Low and good quality coal found together. this leads to selective mining which is wasteful

b. Not enough high grade coking coal and imports are needed

c. Washing, dressing, blending of coal is needed as by washing the ash content goes down and transportation is easier.

d. Open cast mining leads to pollution and smuggling

e. Deep mining techniques are primitive so high casualty

f. Coal field contain coal bed methane but no policy for allowing joint exploration of both. Hence methane allowed to escape this is wasteful.

g. Poor connectivity of coal to consumer locations. The productivity of mines is less as output per man shift is less than that of developed countries.

Coal

Gasification:

It is a

technique of extracting coal from deep, unrecoverable mines

where manual mining is costly or impossible.

Two wells are dug:

a. Injection well: water + oxygen + gasification agent pumped from one well.

b. Production well: Synthetic gas comes out.

Advantages:

a. Synthetic gas is used for generating electricity, making fertilizers and hydrogen

b. Toxic wastes remain underground

c.

Less

water

needed than conventional mining and hydraulic fracking.

Natural Gas

- It is found in sedimentary rocks where other hydrocarbons are trapped. It is either found alongside other hydrocarbons like crude oil or alone.

- Constituents:

- 1. Methane – major constituent

- 2. Propane

- 3. Butane

- 4. Ethane

- 5. Hydrogen sulphide – waste

- Propane and butane are used in LPG.

- It needs airtight trucks for storage and leak proof pipes for transport. This increases capital cost. Natural gas occupies four times the space of a gasoline equivalent substance. In India natural gas exists alongside oil. No exclusive reserves are found and sometimes natural gas has to be re-injected in the field to get the oil to come to the surface.

- LNG terminals – NG is liquefied then transported to long distances. Liquefaction plant is at exporting country and re-gasification at importing countries.

- Tight

gas

sands:

- They are present

in the deep sedimentary sands. The reservoirs have no natural

fractures so hydraulic fracturing technique is used to extract

gas. Initially drilling is done where a fluid is injected by

which the gas comes to the wells.

Gas requires an expensive transport network in terms

of pipes.

- Cross

border

pipelines:

- 1. Turkmenistan – Afghanistan – Pakistan – India [TAPI] – the pipeline passes through hostile regions. International agency not willing to take responsibility to lay the pipeline. Since Turkmen law doesn’t allow that agency to get a stake in the gas field that shall feed the pipeline.

- 2. Iran Pakistan India [IPI] – Iran constructed pipeline on its part

and gave loan to Pakistan for construction of pipeline. But

due to US sanctions on Iran the loan was cancelled. This

pipeline too passes through hostile region of Baluchistan and

the supply of gas can be cutoff by Pakistan anytime.

- 3.A deep sea pipeline from India to Iran is also being discussed. Another gas pipeline via Russia and central Asia via TAPI line to India are in discussions.

Fig 5: Proposed Pipelines of Natural Gas

Fig 5: Proposed Pipelines of Natural GasSolved Question Papers

Q.In India the steel production industry requires the import of (UPSC CSAT 2015)

saltpeter

rock phosphate

coking coal

All of the above

Ans .

Saltpetre (Potassium nitrate) is not used in the production of steel.

It requires 0.8 tonnes coking coal to produce one tonne of steel.

Chapter Review

Score more than 80% marks and move ahead else stay back and read again!