-

Chapter 7: INDUSTRIAL LOCATION FACTORS - METALS INDUSTRY

Aluminum Industry

Aluminum industry is located close to bauxite ore regions. Bauxite is the raw material that is refined to get aluminum. The process of refining is highly weight losing as only 1 ton of aluminum is obtained from 6 tons of bauxite ore. Bauxite is found in tropics where limestone rocks are weathered.

Step 1: Bauxite ore is crushed, washed and mixed with caustic soda to remove impurities.

Step 2: It is then dried in large furnaces to get alumina.

Step 3: Electrolysis of alumina powder is done to get aluminum as huge amount of electricity is needed such plants are located close to areas where cheap electricity is available.

The process of converting bauxite to alumina is done at the site of raw material.

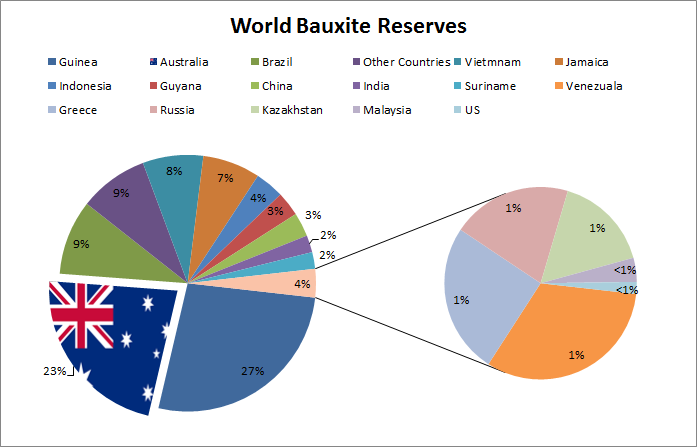

Fig 1: Bauxite Reserves

Fig 2: Bauxite production

Copper Industry

Location factor for copper industry is same as aluminum industry however refining stages are different.

Step 1: Copper ore has to be concentrated and sulphur and oxygen impurities have to be removed. It is soaked in water and mixed in oils. 2.5% of original matter remains and due to high weight loss such industry are located close to source of raw materials.

Step 2: Concentrated ore is called blister copper and is 99% pure but still can't be used for manufacturing. Gold, silver, lead and zinc impurities are present and have to be removed. Electrolysis is needed to get these impurities removed. In this stage too weight loss is low and hence availability of cheap electricity determines the location of industry.

Note: Sulphur dioxide is a by product of concentration process and is useful in manufacturing of phosphoric acid. Rock phosphate is imported and the sulphuric acid is used to get phosphoric acid. This is needed in phosphate fertilizers.

Challenges of Indian Copper Industry:

- Special copper alloys are imported as technical know how for manufacturing them isn't available in India.

- The supply to demand is mismatched and met through imports.

- The technology for making downstream copper products isn't available and obsolete methods of concentration and refining lead to air pollution.

- Scrap metal based copper smelters are still not established in India however they use a fraction of the energy needed by refineries.

- Extraction of metals like cobalt and nickel during copper concentration isn't present in India.

- Average quality of copper produced and high manpower to per tonne of finished copper compared to developed countries is seen.

Note:

Lead and zinc also are obtained by concentrating ore

using certain oils. This concentration is high weight loss

procedure. The second stage involves refining by

electrolysis and needs high electricity. So location factors

are same.

Questions for UPSC Mains

Explain factors for the growth of Aluminum industry?

Explain factors for the growth of Copper industry?